2020 Technology Outlook - Finishing

Print Finishing Technology Outlook Webinar

Listen to Trish Witkowski discuss the latest developments in mailing and finishing. This 30-minute LunchNLearn webinar highlights the latest technology and product announcements, and trends in mailing and finishing. Get the lowdown on new features, capabilities, and applications that can give your business a competitive edge.

What you'll learn:

- New developments and trends in mailing and finishing

- New products from major industry vendors

- New features, capabilities, and applications

Featured Articles

Don’t Forget to Finish It!

Virtually every printed document requires some type of finishing. The expanding array of digital printing methods has changed the nature of finishing from large-scale devices focused on offset printing to automated methods that often occur alongside a production digital printer. To reach its true potential, the role of finishing must evolve as well. Recent research from Keypoint Intelligence – InfoTrends offers important insights on how print service providers (PSPs) can leverage finishing to win business and drive profitability.

Actega EcoLeaf (aka Nano Metallography) Digital Metallization Ready for Prime Time

At drupa 2016, Landa Labs introduced Nano Metallography, a new metallization technology to replace foils for embellishments. This process is designed to produce zero waste at less than half the cost of foil. In February of 2017, Actega Metal Print, a division of Altana AG, acquired the technology and rebranded it EcoLeaf. The solution is now going into beta and will be fully commercialized in time for drupa 2020.

How To Sell Enhanced Printing

“Digital enhancement” or enhanced printing is one of the hottest trends in the industry and has been the talk of many recent trade shows—but enhanced print doesn’t sell itself. Pat McGrew offers some tips and strategies for selling enhanced printing to maximize ROI.

Embellishments: What’s Old Is New Again and Still Adds Value!—Part 2

Embellishment has been a function of print production for as long as there has been printing. In fact, it almost goes back to the beginning of the writing of documents. There is no doubt that embellishment does add value to the printed product. Especially with the more recent introduction of digital embellishment technologies designed to complement digital printing. Now that embellishments have finally begun to capture market awareness, new developments are happening all the time. In part 2 of this series, David Zwang will look at new mainstream technologies that add embellishments and value to print and packaging production.

Embellishments: What’s Old Is New Again and Still Adds Value!—Part 1

Embellishment has been a function of print production for as long as there has been printing. In fact, it almost goes back to the beginning of the writing of documents. There is no doubt that embellishment does add value to the printed product. Especially with the more recent introduction of digital embellishment technologies, designed to complement digital printing technologies. New developments in digital embellishment are happening all the time now that it has finally begun to capture market awareness. In part one of this two-part feature, David Zwang will look at the added value and long history of embellishments.

News

Introducing the James Burn EasyPunch: A Revolution in Automatic Binding Punch Technology

At Printing United 2023 Tecnau Shows Continuous Cut to Stahlfolder

palamides Brings New Innovative Collect to Box Solution to Printing United Expo 2023

ExpressCutPRO™ Revolutionizes Digital Die Cutting for Enhanced Efficiency and Profits

Kongsberg PCS to Spotlight Cutting Edge Automation and Integrated Workflows at PRINTING United

Layflat.com Features LF 2000 All-in Max at PRINTING United

Graphco Launches SD-Italy Hybrid CNC Routing & Cutting Technology at PRINTING United

Metalloy Italiana Signs a Service Contract with Flexa for a More Sustainable World

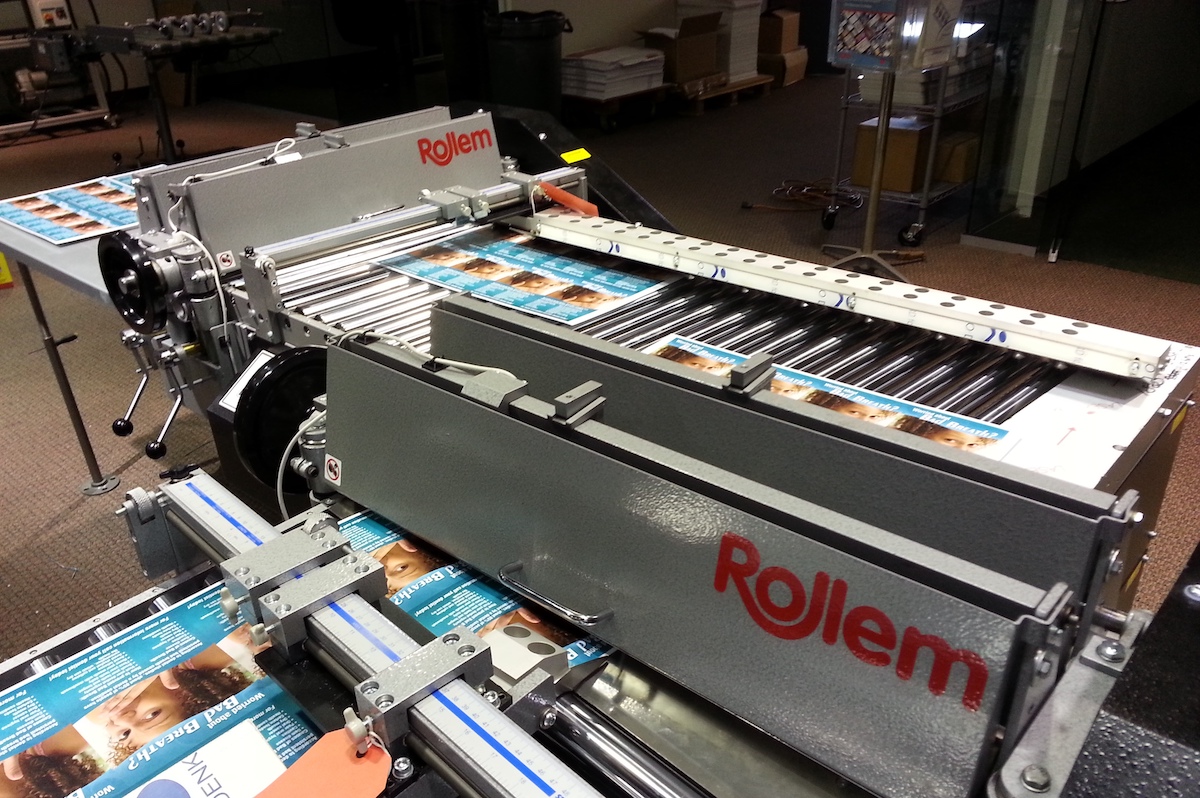

Rollem International Announces Live Demonstrations at Printing United

Introducing the Digifav Duplex Laminator: Two-Sided Thin Gauge Lamination in Half the Time

Duplo USA Set to Showcase B2 Finishing Solutions at PRINTING United 2023

SEI Labelmaster’s Speed and Versatility Increase Opportunities and Profits at TLF Graphics

Taktiful Announces the Release of its Groundbreaking Case Study with The Kennickell Group

Hasler Solutions Introduces the First 5-Meter Wide Digital XY Flatbed Cutter

Sodexo Enterprises Adds Plockmatic BLM5050 Booklet Maker

Ultimate TechnoGraphics and Duplo International Expand Partnership for B2 Digital Printing Market

Summa Sets New Reference for Cutters (Again) with the S Class 3 Series

New Intec SC6500 Auto-Feeding Digital Die-Cutter for Lightweight Packaging and Label Production

palamides Showcases gamma Automated Delivery at Horizon Finishing First Event 2023

Zund America Presents: Digital Cutting Days ‘23

High-Speed Rotary Hot Stamping and Embossing by Steuer a Big Hit at FSEA Embellishment Conference

Davis Direct Purchases Stahlfolder KH 82 from HEIDELBERG to Boost Efficiency for Signature Folding

Horizon and Ultimate TechnoGraphics Announce Global Partnership

Kongsberg PCS Launches New State-of-the-Art Customer Experience Center

FSEA Commends Updated APR Design® Guidance for Metallized Transfer Products

Fully Automated Laser System Expands Sign Ink’s Capabilities and Profit Potential

Apex3R Takes Center Stage as Kongsberg PCS Unveils new MultiCam Demo Center

LabelExpo: POLAR Presents Fastest Die Cutter on the Market

Kongsberg PCS Spotlights Ease of Automation at CorrExpo 2023

PressOn Offer to Demo New Marabu Laminator

Cosmetic and Pharma Packaging: Why EXPERTFOLD 50/80/110 Is Key to Box Quality and Compliance

Now Available! Taktiful and WhatTheyThink’s Landmark Digital Embellishment Study

Bobst North America to Open State-of-the-Art Competence Center in Atlanta

Featured Technology Partner

Automate Cutting with the Jetstream Rotary XY Slitter

Jetstream’s XY Slitter is the preferred choice for higher volume professional converting of postcards, business cards, retail shelf tags and photo books. Speeds up to 5,000 sph with 100% cutting accuracy plus scoring and perforating. This fully automated system offers a new flexible stacker, auto-collator, bar code reader or in-line folder/gluer to maximize any type of product delivery. Streamline finishing with the 24” or 30” Jetstream XY Slitter.

Muller Martini's Digital Solutions Portfolio

Smart production is critical in today’s digital finishing environment as shorter runs down to book of one become more commonplace and workflows become more complex. That’s why our Finishing 4.0 principles of automation, connectivity, variability, touchless workflow and hybrid systems are embodied throughout a Digital Solutions portfolio that delivers ultra-efficient production of saddle stitched or perfect bound products for either hardcover or softcover applications.

Ultimate Bindery - Your Workflow's Finishing Touch

Ultimate Bindery is a standalone software solution designed to fill the gap between prepress and finishing. Ultimate Bindery® can take any imposed job and complete it with all the necessary parameters needed to automatically set up your finishing equipment such as perfect binder, saddle-stitcher, cutter, slitter-creaser, 3-knife cutter, etc. It allows to produce variable length products in different quantities, on the fly with no manual make-ready. Ultimate Bindery® is a hub of knowledge of many different finishing devices from different manufacturers and can automate in-line and near-line finishing equipment. It operates as a central location to validate that each job is built respecting the capabilities and constraints of the selected finishing equipment. These validations prevent errors and reduce waste since an alert is sent to the user for them to rectify the situation.

© 2023 WhatTheyThink. All Rights Reserved.